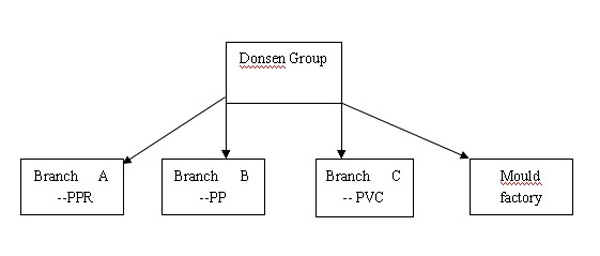

Branch A:

District A is the the Headquarter of Donsen Group. Workshop is mainly responsibility for manufacturing PP-R pipe &fitting.

We have more than 50 sets of injection machines. All injection machines use concentrate feed system. It makes the mixing of raw

materials, transportation becomes integrated and automated. It avoid the trouble of artificial feeding, feed raw materials may occur during pollution, improve the company's productivity.

District A set up specialized mould service shop and equipped with mould serviceman. Once mould turns up problem, we can fix up in the first time flexibly, efficiently. To insure the production carry on well-off.

Branch B:

District B is mainly responsibility for producing CPVC fitting and all kinds of valves. Have professional technical backbone staff valve products injection molding, transfer machines, in order to ensure product quality and production efficiency, thereby improving production costs, improve our products in the market competitiveness.

Branch C:

District C is mainly in charge of PP compression fitting production. We open up the sole workshop, have specialized person in charge of PP compression fitting production; because of high demand of delivery date and warehouse storage capacity. It can enhance the production efficiency, more effective to use the warehouse storage capacity, ensure on time delivery.

Mould Factory:

Mould plant is mainly response for all kinds of plastic mould, especially fitting mould. It has a team of professional mold development and production. We have more than 20 years mould production experience. Moulds are exported to many countries, like: Russia, Ukraine, Turkey etc.