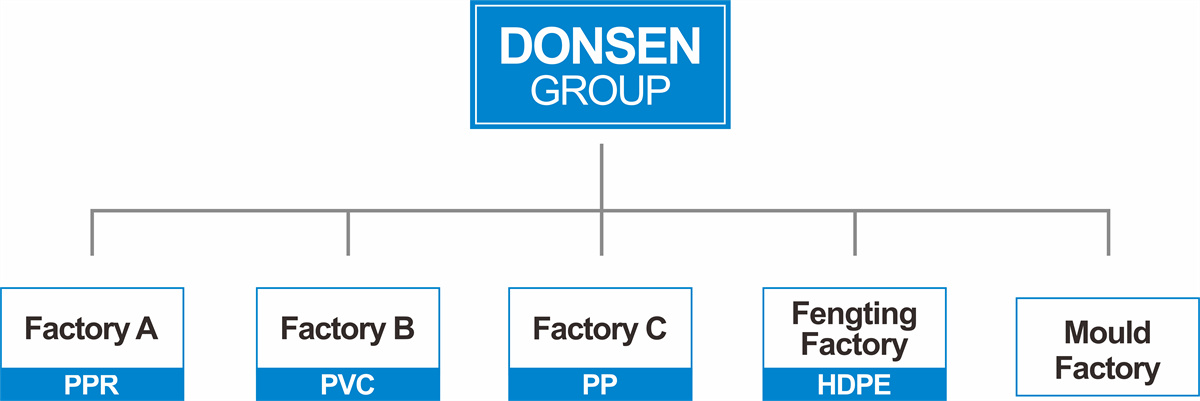

At present, Donsen has three major product production plants, a mold factory and a new production base under construction. Factory A is the company's headquarters. In addition to the office building, the workshop is mainly responsible for the production of PPR pipe fittings, PE pipe fittings and other water supply products and various valves. The workshop adopts a centralized feeding system to directly turn the mixing and transportation of raw materials into integration and automation, eliminating the trouble of manual feeding and possible raw material pollution in the feeding process, It improves the production efficiency of the company.Zone A also has a special mold maintenance workshop and professional mold maintenance personnel. Once there is a problem with the mold, it can be handled at the first time, and solve the problem flexibly and efficiently, so as to ensure the orderly progress of production. Furthermore, the company also specially introduced international advanced PPR-AL-PPR production line, PPR-Firbglass, PPR-coper-PPR production line, double high-efficiency production line, other 9 advanced pipe lines and more than 70 injection molding machines. The company has a special laboratory, which is equipped with a full set of sophisticated testing equipment, pipe hydrostatic testing machine, pipe drop hammer impact testing machine, melt flow rate meter, carbon black dispersion tester, Vicka thermal deformation testing machine and other professional testing equipments. Ukraine, Turkey and so on.

Factory B is the production base of PVC pipe fittings, HDPE pipe fittings on the same floor and other drainage products. There are professional technical backbone personnel for product injection molding and machine adjustment, so as to ensure product quality and production efficiency, so as to better control the production cost of products and improve the competitiveness of our products in the market

Factory C is mainly responsible for the production of agricultural water-saving irrigation series products such as PP compressed pipe fittings. Because this product has high requirements for the production cycle of goods and the storage capacity of the warehouse. Therefore, our company has specially opened a separate production workshop, and a specially assigned person is responsible for the production of the product. Responsibility to people, so as to improve the production efficiency of products, effectively mobilize the material storage capacity of the warehouse and ensure the delivery on time.

Mould factory is mainly responsible for the production of various plastic moulds. At the beginning of the development of Donsen company, it starts from the mold. From the factory owner to the management, many of them are from professional mold technology. At present, the molds of all products in Donsen Group come from self-development and manufacturing, so the factory has a number of professional mold development and production teams. In the mold industry has nearly 20 years of production experience. We have opened many molds for countries all over the world, such as Russia, Ukraine, Turkey and so on.

The new branch under construction is Fengting factory, which will greatly help Donsen to develop pipeline products. Our company will increase the production and promotion of HDPE water supply pipe fittings, HDPE natural gas pipe fittings, HDPE same-layer drainage pipe fittings,siphon drainage pipe fittings, and water-saving irrigation peripheral products after the completion of this sub-base. The establishment of this base will also make a quantum leap in the production of pipe fittings, valves, pipes and other products of Donsen.